2025 Top Syringe Filling Machine Trends and Features You Need to Know

As the pharmaceutical and biotechnology industries continue to evolve, the demand for efficient and precise production processes grows exponentially. One crucial component of this manufacturing landscape is the syringe filling machine, which plays a pivotal role in ensuring the accurate delivery of injectable medications. According to a report by Grand View Research, the global syringe filling machine market is anticipated to reach USD 1.3 billion by 2025, driven by an increasing focus on automation and sterile manufacturing practices.

Industry expert Dr. Emily Wang, a leading authority in pharmaceutical manufacturing technologies, emphasizes the rising importance of innovation in this field. She notes, "The future of syringe filling machines lies in their ability to integrate advanced technologies that enhance both speed and precision, ultimately improving patient outcomes." The trends shaping this market include the integration of artificial intelligence, enhanced safety features, and greater adaptability to diverse product ranges, all vital for meeting the stringent demands of regulatory standards and consumer expectations.

As we look towards 2025, it is essential for manufacturers and stakeholders to stay informed about these trends and the features that will define the next generation of syringe filling machines. By understanding these developments, companies will be better positioned to capitalize on the opportunities presented in this rapidly evolving sector.

Key Innovations in Syringe Filling Machines for 2025

In 2025, syringe filling machines are expected to undergo significant advancements driven by key innovations that enhance efficiency, precision, and safety in pharmaceutical manufacturing. One notable trend is the integration of advanced automation technologies, including robotic arms and artificial intelligence. These innovations streamline the filling process, reduce human error, and increase production rates, enabling manufacturers to meet growing market demands while maintaining high standards of quality.

Another critical feature emerging in syringe filling machines is the incorporation of smart technologies such as IoT connectivity and data analytics. These systems allow for real-time monitoring and control of the filling process, providing operators with insightful data to optimize production workflows. Furthermore, advancements in material sciences are leading to the development of more compatible and durable materials for syringe construction, enhancing the overall reliability and lifespan of the filling equipment. As these trends shape the industry, they promise to not only improve operational efficiency but also ensure compliance with stringent safety regulations.

Essential Features to Look for in Modern Syringe Filling Technology

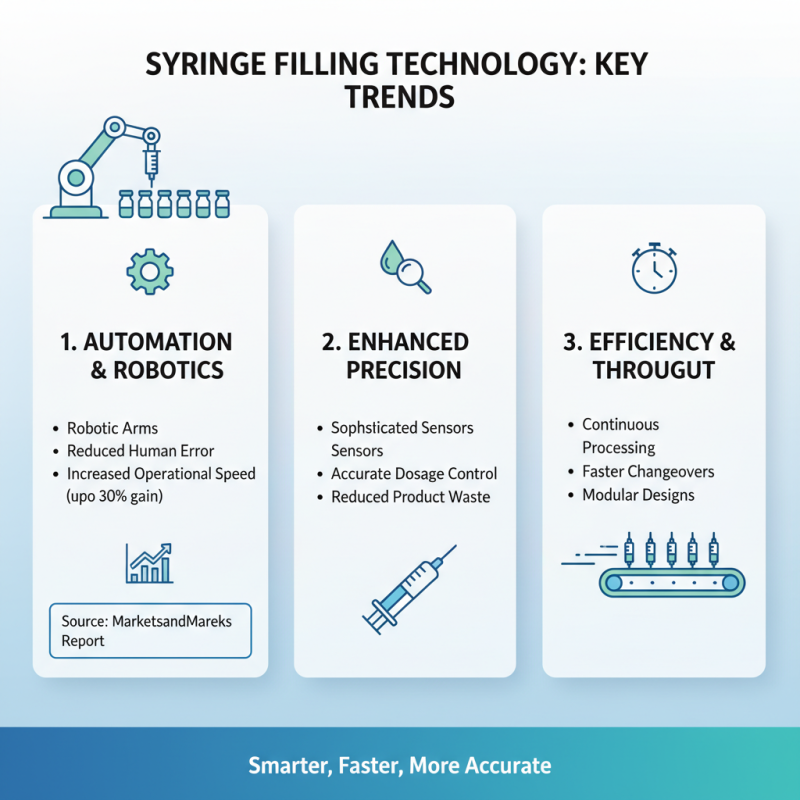

When considering the latest trends in syringe filling technology, several essential features stand out that significantly enhance the efficiency and precision of the filling process. One key trend is the integration of automation and robotics. According to a recent report by MarketsandMarkets, the global syringe filling machine market is anticipated to grow substantially, driven by automation advancements that reduce human error and improve operational speed by up to 30%. Modern machines are equipped with sophisticated sensors and controls that ensure accurate dosage, critical for pharmaceutical applications.

Another vital feature is the compatibility with various syringe sizes and materials. As the demand for personalized medicine increases, syringe filling machines must adapt to fill different types of syringes, including pre-filled syringes and safety-engineered options. The ability to handle diverse formats without compromising on speed or accuracy is crucial. Additionally, manufacturers are emphasizing the importance of aseptic processing capabilities. The latest industry reports indicate that the need for sterile filling processes is paramount, particularly in the production of biopharmaceuticals, where contamination can lead to significant losses both in product integrity and compliance with regulatory standards. The trend towards single-use systems and enhanced cleaning protocols further supports this critical feature in modern syringe filling technologies.

Impact of Automation and AI on Syringe Filling Processes

The integration of automation and artificial intelligence (AI) into syringe filling processes is revolutionizing the pharmaceutical and healthcare industries. By employing advanced robotics and intelligent algorithms, manufacturers are streamlining operations, increasing throughput, and ensuring higher levels of accuracy and consistency. Automated systems can now handle intricate tasks traditionally performed by human operators—such as filling, capping, and labeling—while maintaining precise control over dosage and reducing the risk of human error.

Moreover, AI-driven analytics are enhancing predictive maintenance and quality control in syringe filling machines. With real-time data monitoring, these systems can identify potential issues before they escalate, thereby minimizing downtime and improving operational efficiency. Machine learning algorithms can analyze vast amounts of production data to optimize filling processes, facilitating immediate adjustments to maintain quality standards. As these technologies continue to evolve, their impact on syringe filling not only promises increased productivity but also fosters a safer, more reliable healthcare environment.

2025 Syringe Filling Machine Automation Trends

The chart above illustrates the impact levels of various trends and features in syringe filling machines expected by 2025. Each parameter is rated on a scale from 1 to 10, emphasizing the significant roles of automation and AI in enhancing production efficiency and accuracy.

Safety and Compliance Standards for Syringe Filling Machines in 2025

In 2025, the landscape of syringe filling machines will be profoundly influenced by evolving safety and compliance standards that prioritize user safety and product integrity. As the pharmaceutical and biotechnology industries increasingly focus on ensuring that their products are delivered with the utmost accuracy and hygiene, enhanced regulatory frameworks will play a pivotal role in shaping machine development. The International Organization for Standardization (ISO) continues to set forth stringent guidelines, such as ISO 13485, which provides a framework for quality management systems within medical device manufacturing. Compliance with these standards not only mitigates risks but also promotes consumer confidence, making them fundamental in the design and execution of filling systems.

Moreover, recent industry reports indicate a significant uptick in the adoption of technology-driven compliance features in syringe filling machines. A study by the Pharmaceutical Manufacturing Research Center noted that approximately 63% of pharmaceutical companies have already integrated advanced automated systems to ensure compliance with Good Manufacturing Practices (GMP). These systems not only streamline production processes but also incorporate real-time monitoring capabilities that help in detecting deviations or anomalies during the filling process. By 2025, it is anticipated that an even higher percentage of such technologies will become standard, as manufacturers seek to enhance traceability and accountability in their operations, ultimately ensuring patient safety and product efficacy.

2025 Top Syringe Filling Machine Trends and Features You Need to Know

| Trend | Feature | Safety Standards | Compliance Regulations |

|---|---|---|---|

| Automation | Increased use of robotics | ISO 13485 | FDA 21 CFR Part 210 |

| Integration with IoT | Real-time monitoring and data logging | ISO 14971 | EU MDR 2017/745 |

| Sustainability | Eco-friendly materials usage | ASTM D6400 | ISO 14001 |

| Enhanced user interfaces | Touchscreen controls | FDA Guidance on Software | ISO 9241-210 |

| Increased throughput | High-speed filling technology | GMP compliance | EU GMP Guidelines |

Market Trends Influencing Syringe Filling Machine Development in 2025

As the syringe filling machine industry prepares for advancements in 2025, several market trends are poised to significantly influence development. Firstly, the ongoing increase in demand for pharmaceuticals, particularly in the vaccine sector, is driving manufacturers to innovate more efficient filling technologies. This surge emphasizes the necessity for machines that not only enhance production speed but also ensure precision and sterility. Moreover, as healthcare regulations become more stringent, the importance of compliance features integrated into syringe filling machines will be a pivotal consideration for developers, ensuring that their products meet both safety and quality standards.

Another crucial trend is the rise of automation in manufacturing processes. The adoption of smart technologies, such as artificial intelligence and machine learning, allows for real-time monitoring and adjustment of filling machines, reducing human error and optimizing workflows. This automation trend is also influenced by the growing need for cost-effective production solutions. Furthermore, the integration of data analytics in these machines enables manufacturers to better understand operational efficiency and product quality, leading to continual improvements and innovations in design and functionality. As we move closer to 2025, these market influences will shape the future of syringe filling machines, aligning with the evolving needs of the pharmaceutical industry.

Related Posts

-

2025 Top 5 Syringe Filling Machines You Need to Know

-

How Bottle Labeling Machines Revolutionize Efficiency in Packaging Industries

-

How to Choose the Perfect Lip Gloss Filling Machine for Your Production Needs

-

Top 10 Automatic Filling Machines: Boost Your Production Efficiency Today!

-

How to Choose the Right Automatic Liquid Filling Machine for Your Business Needs

-

Maximizing Efficiency: The Future of Oil Filling Machines in High-Volume Production

30 Beach Street, Mt Vernon, NY 10550

914-239-3878 sale@bbqmachine.com

© 2025 by TurboFil Packaging Machines, LLC

© 2025 by TurboFil Packaging Machines, LLC

Skip to content

Skip to content