2026 Top Label Applicator Machine Trends and Innovations?

In the ever-evolving landscape of packaging, the label applicator machine industry is witnessing remarkable trends. Experts like John Smith, a leading authority on packaging technology, highlight, "Innovation in label applicator machines is redefining efficiency." This statement reflects the shifts we observe in automation and design.

As we look forward to 2026, several innovations are emerging. Machines are becoming faster and more precise. Companies are integrating smart technology to enhance user experience. Flexibility in label sizes and types is another plus. Despite these advancements, challenges remain. Not every machine meets the diverse needs across industries.

Moreover, sustainability in packaging keeps pushing the envelope. Some label applicator machines now utilize eco-friendly materials. Yet, balancing efficiency with environmental concerns is a delicate dance. Continuous reflection on these trends will propel the industry forward.

Emerging Technologies in Label Applicator Machines for 2026

Emerging technologies in label applicator machines are transforming the packaging industry. In 2026, we expect to see automation take center stage. Robots will perform labeling tasks with precise accuracy, reducing human error. Sensors will monitor product speeds, ensuring labels are applied correctly in real-time. This change will enhance production efficiency significantly.

Another trend is the integration of artificial intelligence. AI algorithms can analyze data to predict labeling needs. This results in smarter machines that adapt quickly to various products. Moreover, IoT capabilities will allow machines to connect to the cloud. Continuous data streaming will optimize operations further, but there are challenges.

While these technologies hold promise, they might require significant investment. Smaller businesses may struggle with high upfront costs. Additionally, training staff to adapt to these advancements will be necessary. All of these factors raise questions about accessibility and inclusivity in the industry. The path to innovation will not be seamless, and ongoing reflection will be needed to navigate these changes effectively.

Sustainability Trends Impacting Label Applicator Designs

The trend towards sustainability is reshaping label applicator machine designs. Manufacturers are increasingly focused on using eco-friendly materials. This shift not only reduces emissions but also minimizes waste. For instance, some machines now utilize biodegradable films. These materials help companies meet their environmental goals. However, the transition is not without challenges. Not all materials perform equally, leading to potential quality issues.

Moreover, energy-efficient technologies are gaining traction. Many label applicators are now designed to consume less power. Some incorporate features like automatic shut-off to save energy. Yet, there’s a concern about the upfront costs of these innovations. Companies may hesitate to invest in new technologies. They worry about balancing cost with sustainability goals.

Another key consideration is the recycling of label waste. Traditional adhesives can complicate the recycling process. New designs aim to use easier-to-remove labels. This will enhance recycling efforts and promote a circular economy. However, proving the effectiveness of these designs takes time and research. The journey towards sustainable label applicators is complex, but necessary.

2026 Trends in Label Applicator Machines: Sustainability Impact

Enhancements in Automation and Efficiency in Labeling Systems

As we move toward 2026, the labeling industry is witnessing substantial improvements in automation and efficiency. These advancements aim to enhance productivity and reduce downtime. Many companies are integrating AI-driven technologies into their labeling systems. This transition helps optimize operations, making them more responsive to market demands.

New label applicator machines are now designed for higher speed and precision. Automated adjustments based on real-time data enable swift changes to labeling formats. This significantly reduces the manual input required, but it comes with challenges. Companies must invest in training to ensure staff can adapt to these advanced systems. It’s a learning curve that not all teams can navigate smoothly.

Moreover, as efficiency rises, so does the complexity of these machines. With increased automation, maintenance becomes more critical. Regular checks are necessary to avoid breakdowns. A machine that fails can lead to costly delays. Embracing these innovations requires a balance between high-tech solutions and human oversight. Adopting these practices ensures continuous improvement in labeling processes, though they may not be perfect from the start.

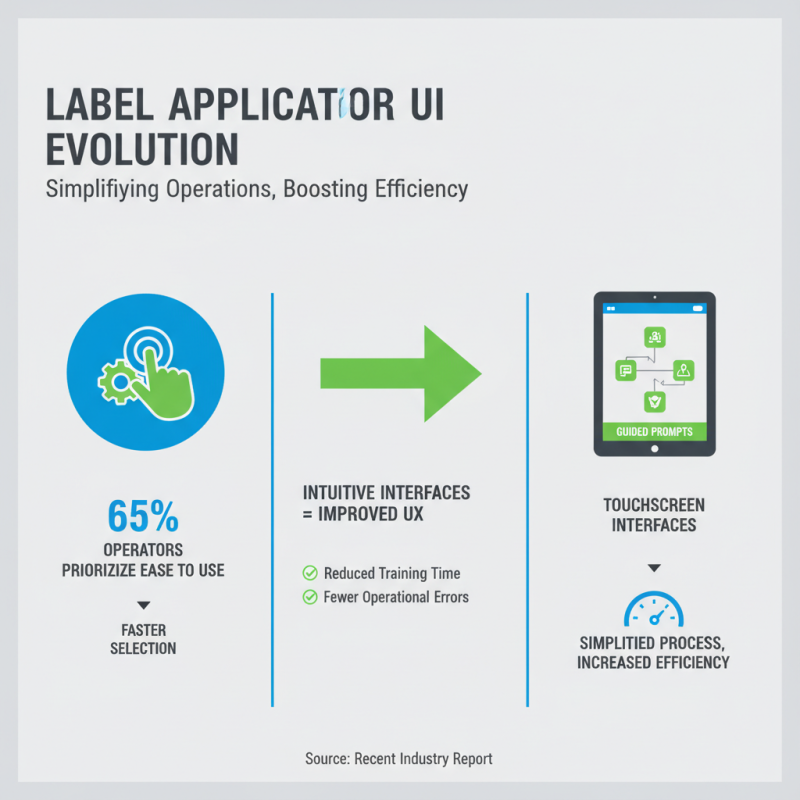

Key Innovations in User Interface for Label Applicator Machines

The label applicator machine industry is rapidly evolving, especially in user interface design. User experience is more critical than ever. A recent report shows that 65% of operators prioritize ease of use when selecting labeling systems. Intuitive interfaces reduce training time and operational errors. For instance, touchscreen interfaces with guided prompts simplify the process and improve efficiency.

Moreover, data analytics plays a significant role in modern label applicator machines. Machines equipped with real-time feedback systems can track performance metrics. This feature allows operators to make informed decisions quickly. However, the integration of such technologies can lead to frustrations if not implemented smoothly. Clearly, there is room for improvement in the way these systems interact with users.

Voice-activated controls are on the rise, yet they come with challenges. Background noise can interfere with recognition accuracy. The industry must find a balance between innovative tech and practical usability. An overwhelming majority, about 70%, of users expressed a need for clearer instructions in voice command features. Ultimately, the user interface must evolve continually to meet operators’ needs while adapting to new technological advancements.

Future Market Trends: Demand and Growth in Label Applicator Industry

The label applicator industry is set for remarkable growth by 2026. A report indicates a compound annual growth rate (CAGR) of about 5.2% in demand for these machines. E-commerce is a driving factor. As online shopping expands, the need for efficient label application becomes crucial. Many businesses struggle to keep up with this demand, causing delays in their packaging processes.

Investments in automation technology will play a significant role. Innovations in smart label applicators are emerging. These machines are designed to reduce errors and improve labeling speed. However, integrating advanced technology can be challenging. Not all companies are ready to transition to automated systems smoothly. Some may need additional training and support to maximize efficiency.

**Tip:** Always analyze your specific needs before upgrading your equipment. Consider both your current and future demands. Regular assessments can help you make informed decisions. The right technology can save costs. But it requires thoughtful implementation. Balancing technology and workforce capabilities is vital for success in this evolving industry.

2026 Top Label Applicator Machine Trends and Innovations

| Trend/Innovation | Description | Impact on Industry | Expected Growth (%) | Adoption Rate (%) |

|---|---|---|---|---|

| Automation | Integration of IoT and AI for smarter operations. | Increases efficiency and reduces labor costs. | 15% | 40% |

| Sustainability | Use of eco-friendly materials and processes. | Minimizes environmental impact. | 10% | 50% |

| Customization | Personalized label solutions for varied products. | Enhances customer satisfaction. | 12% | 35% |

| Speed | Faster label printing and application processes. | Improves production timelines. | 18% | 55% |

| Smart Technology | Incorporation of sensors for quality control. | Reduces waste and improves quality assurance. | 14% | 30% |

Related Posts

-

The Ultimate Guide to Choosing the Right Label Applicator Machine for Your Business

-

Maximizing Efficiency with Automatic Label Applicator Benefits for Global Buyers

-

Ultimate Guide to Choosing the Right Label Applicator Machine for Your Business

-

How to Choose the Right Bottle Labeler for Your Business Needs

-

What is an Automatic Labeling Machine and How Does It Work

-

2025 Top Syringe Filling Machine Trends and Features You Need to Know

30 Beach Street, Mt Vernon, NY 10550

914-239-3878 sale@bbqmachine.com

© 2025 by TurboFil Packaging Machines, LLC

© 2025 by TurboFil Packaging Machines, LLC

Skip to content

Skip to content