What is an Automatic Labeling Machine and How Does It Work?

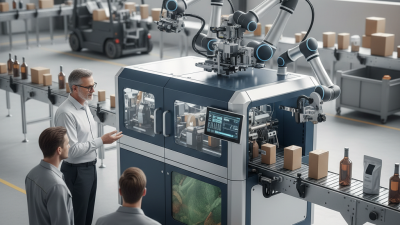

An automatic labeling machine is a vital part of modern packaging. It streamlines the process of labeling products. As John Smith, an expert in packaging automation, states, "Efficiency in labeling can drastically reduce production time." This technology aids various industries, from food and beverage to pharmaceuticals.

These machines use advanced technology to apply labels quickly and accurately. They ensure consistent quality and reduce labor costs. However, not all machines are perfect. Some can struggle with label alignment or adhesion under certain conditions. Such challenges remind manufacturers to regularly maintain their equipment.

Investing in an automatic labeling machine can lead to greater efficiency. Yet, it's important to consider the right type for your needs. A poorly chosen machine can create more problems than it solves. Balancing efficiency and quality is critical for any production line.

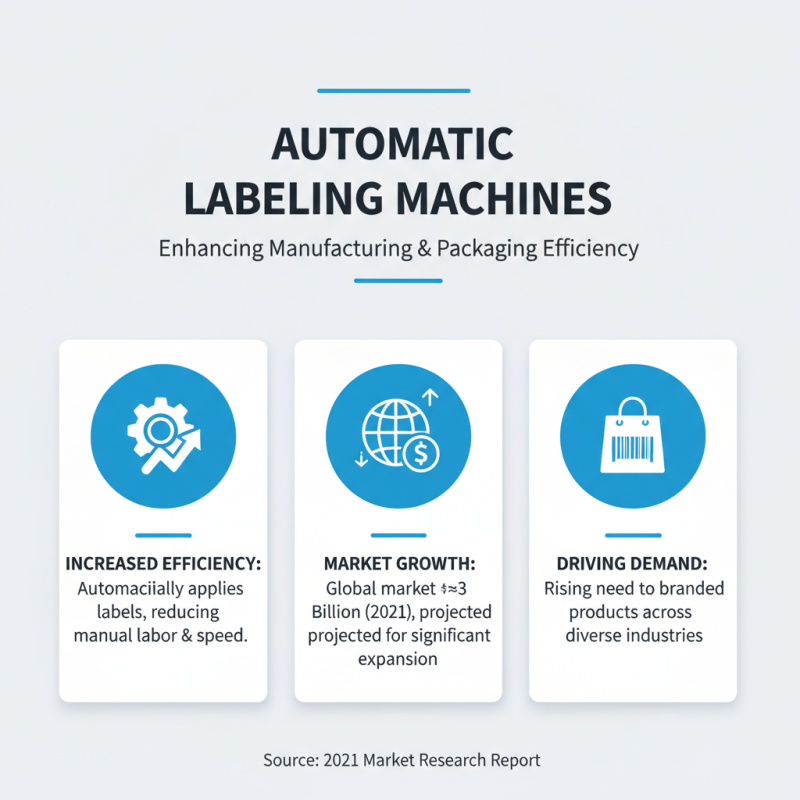

Definition and Overview of Automatic Labeling Machines

Automatic labeling machines are crucial in modern manufacturing and packaging. These machines enhance efficiency by applying labels to products automatically. According to a 2021 market research report, the global automatic labeling machine market was valued at approximately $3 billion and is expected to grow significantly. This growth is driven by the increasing demand for branded products in various industries.

The operation of these machines is relatively straightforward. They utilize advanced technology, including sensors and programmable logic controllers. The labeling process involves identifying the correct product and applying the label with precision. However, challenges remain. Not all machines can handle diverse packaging shapes and sizes effectively. Some may struggle with misaligned labels, which can impact product presentation. It’s essential to choose machinery that fits specific production needs.

Moreover, many facilities experience downtime due to maintenance or calibration issues. Regular checks are necessary to ensure proper functionality. Reports indicate that inefficient labeling processes can lead to increased operational costs. As businesses aim for a competitive edge, investing in high-quality labeling systems becomes paramount, even though finding a perfect solution can be complex.

Key Components and Mechanisms of Automatic Labeling Machines

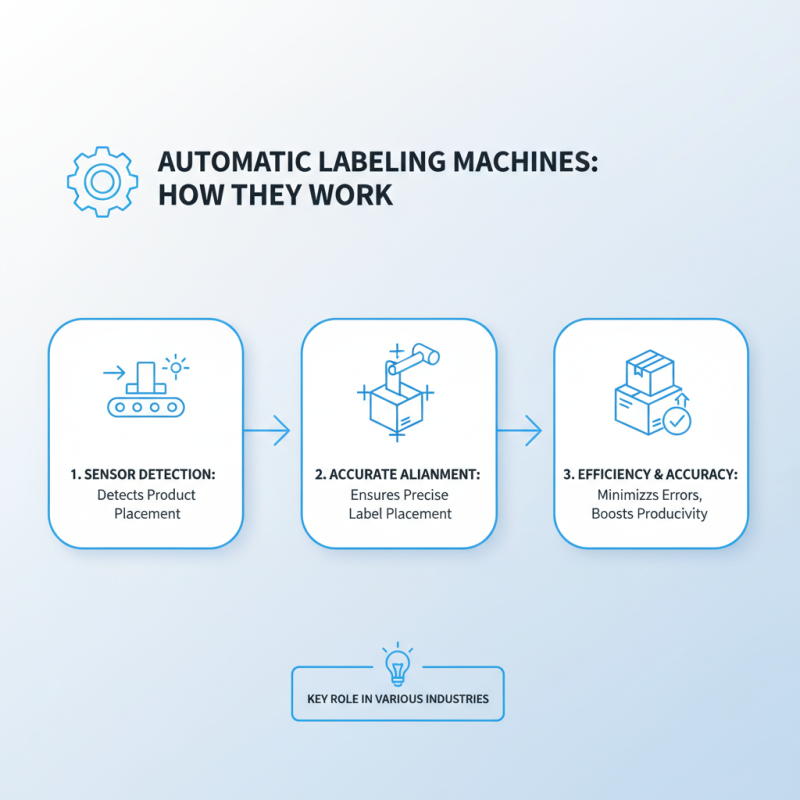

Automatic labeling machines are crucial in modern packaging industries. They enhance efficiency by applying labels to products quickly. Key components include the labeling head, conveyor system, and sensors. The labeling head accurately places labels on containers. A conveyor moves products through the labeling process. Sensors ensure that labels are applied properly and detect any misalignment.

Industry reports indicate that over 30% of packaging efficiencies come from automation. This highlights the importance of these machines. However, there are challenges. Mislabeling can lead to recalls and damage brand trust. In one instance, a major company faced significant losses due to labeling errors. Such incidents remind manufacturers to regularly maintain these machines. Lack of maintenance can lead to inconsistent labeling accuracy.

Moreover, the technology used in sensors can sometimes fail. This may cause delays in production lines. On average, these delays cost companies up to $500,000 annually. Training staff to manage these issues is essential. Regular updates in technology also mean that operators must be adaptable. Overall, automatic labeling machines offer a blend of precision and speed. Yet, they require diligence to minimize risks.

What is an Automatic Labeling Machine and How Does It Work? - Key Components and Mechanisms of Automatic Labeling Machines

| Component | Description | Function | Common Applications |

|---|---|---|---|

| Label Dispenser | Device that removes labels from a backing material. | Automatically feeds labels to the labeling area. | Beverage bottles, food packaging. |

| Label Application System | Applies the label to the product. | Ensures proper placement and adhesion. | Pharmaceuticals, cosmetics. |

| Conveyor System | Moves products through the labeling process. | Streamlines workflow and increases efficiency. | Industrial manufacturing. |

| Control Interface | User interface for operating the machine. | Allows for adjustment of settings and monitoring of operations. | Packaging lines. |

| Sensors | Detects products and labels. | Ensures accurate placement and timing. | Food, electronics. |

Types of Automatic Labeling Machines and Their Applications

Automatic labeling machines play a crucial role in various industries, ensuring efficiency and precision in product labeling. These machines come in different types, each tailored to specific applications. For instance, the pressure-sensitive labeling machine is favored in the food and beverage sector. This machine applies adhesive labels easily, making packaging smooth and effective.

Another common type is the shrink sleeve labeling machine, which is prevalent in the cosmetic and pharmaceutical industries. Shrink sleeves conform to the shape of containers, providing full-coverage branding. According to a recent report, the global automatic labeling machine market is projected to reach $6 billion by 2026. This growth reflects a rising demand for automation in packaging lines.

Tips: When choosing a labeling machine, consider the type of product and container shapes. Proper alignment helps avoid labeling errors. If you are unsure about machine compatibility, consult the machine specifications thoroughly.

A wrap-around labeling machine is also gaining traction, suitable for cylindrical products like bottles. However, it might not perform well on irregular shapes. This limitation could lead to wasted resources and increased downtime. Companies should weigh their choices carefully.

Working Principles: How Automatic Labeling Machines Operate

Automatic labeling machines play a vital role in many industries. They are designed to apply labels efficiently on products or packages. The working principle involves a series of processes that ensure the label is placed accurately. Typically, these machines use sensors to detect product placement and label alignment. This technology minimizes errors, increasing overall productivity.

According to a ReportLinker study, the global labeling equipment market is expected to grow by 3.7% annually through 2025. This growth reflects the critical need for efficiency in production lines. However, some businesses report challenges in integrating these machines into existing workflows. Misalignment can still occur, leading to wasted materials and increased costs.

The technology behind automatic labeling is constantly evolving. Modern machines can handle various shapes and sizes, responding to changing market demands. Yet, adapting to new models can sometimes be disheartening. Employees may need training to maximize potential benefits. Continued evaluation of these systems is essential for companies to ensure they meet operational goals efficiently.

Benefits and Limitations of Using Automatic Labeling Machines

Automatic labeling machines are vital in the packaging industry. They provide efficiency by applying labels quickly and accurately. This technology reduces human errors, ensuring that products are consistently labeled. It helps maintain brand integrity. However, there are some limitations to consider.

The benefits are clear. Time savings are significant with these machines. High-speed production lines depend on them. Additionally, they can easily adapt to different label sizes. This versatility enhances production adaptability. Yet, the initial investment can be daunting. Not every business can afford this cost.

Maintenance can be challenging, too. Regular servicing is needed to keep the machines operational. Breakdowns can lead to delays, affecting overall productivity. Finding skilled technicians might prove difficult. Depending heavily on technology can create issues if not managed carefully. The balance between efficiency and cost-effectiveness requires continuous reflection.

Automatic Labeling Machine: Benefits and Limitations

This chart illustrates the performance metrics of automatic labeling machines, highlighting their strengths and weaknesses in various aspects like speed, accuracy, cost, flexibility, and maintenance. The values represent relative performance on a scale from 0 to 100.

Related Posts

-

What is an Automatic Labeling Machine and How Does It Work

-

The Ultimate Guide to Choosing the Right Label Applicator Machine for Your Business

-

How to Choose the Best Vial Labeling Machine for Your Business Needs

-

2026 Top Label Applicator Machine Trends and Innovations?

-

2025 How to Choose the Best Lotion Filling Machine for Optimal Efficiency

-

7 Essential Tips for Choosing the Perfect Bottle Labeler

30 Beach Street, Mt Vernon, NY 10550

914-239-3878 sale@bbqmachine.com

© 2025 by TurboFil Packaging Machines, LLC

© 2025 by TurboFil Packaging Machines, LLC

Skip to content

Skip to content