How to Choose the Best Oil Filling Machine for Your Business Needs

Choosing the right oil filling machine is crucial for any business handling liquid products, as it directly impacts efficiency, cost, and product quality. According to industry expert David Thompson, a seasoned engineer in packaging solutions, “The right oil filling machine can transform your production line, ensuring precision and reliability.” This statement encapsulates the importance of making informed decisions based on the unique requirements of your operation.

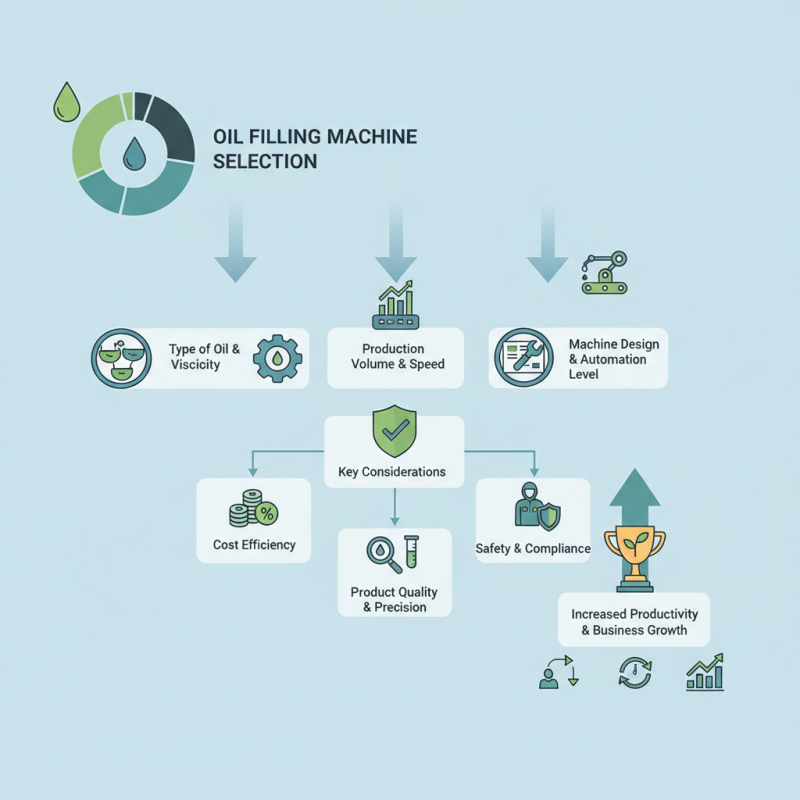

When selecting an oil filling machine, businesses must consider various factors, including the type of oil to be filled, production volume, and the overall design of the machine. Understanding these specifications is essential to optimize filling processes and maintain high standards of safety and quality. As the demand for oil products continues to grow, finding the right machinery can lead to significant advantages over competitors.

In this guide, we will explore key considerations and features to look for in an oil filling machine, helping you navigate the complexities of the market and ultimately choose the best fit for your business needs. Whether you are a start-up or an established enterprise, making the right choice in your oil filling equipment can pave the way for increased productivity and success.

Understanding Different Types of Oil Filling Machines Available in the Market

When selecting the best oil filling machine for your business, understanding the different types available in the market is crucial. The primary categories include volumetric, gravimetric, and pressure filling systems, each designed to meet specific operational needs. Volumetric machines, which fill containers based on predetermined volume measurements, are particularly popular in the food and beverage industry. According to a 2022 market analysis report by Grand View Research, the volumetric filling machine segment alone is expected to grow at a CAGR of 5.2% over the next five years, reflecting its widespread adoption and reliability.

Gravimetric filling machines, on the other hand, utilize weight to determine the amount of product dispensed. This method is favored for its precision and is commonly deployed in industries requiring high accuracy, such as pharmaceuticals and cosmetics. The global market for gravimetric filling equipment is projected to experience significant growth, with an anticipated increase in demand from manufacturers focused on reducing waste and ensuring product consistency. Moreover, pressure filling machines, which use pressure differentials to facilitate the filling process, are increasingly used for viscous liquids, providing an efficient solution for businesses aiming to enhance throughput and reduce cycle times.

Understanding the operational requirements and production scales of your business will guide you in choosing the right machine type. Reports indicate that investing in the appropriate oil filling technology can significantly improve productivity, with some machines capable of operating at speeds exceeding 200 containers per minute, streamlining production processes and maximizing efficiency. By aligning your choice of oil filling machine with industry standards and production demands, you can better equip your business to meet market challenges.

Key Industry Standards and Regulations for Oil Filling Machinery

When selecting an oil filling machine, it's crucial to be aware of the industry standards and regulations that govern such machinery. These guidelines ensure that the equipment operates efficiently and safely, while also adhering to local and international standards regarding quality and safety. Key regulations may include those from organizations such as the Food and Drug Administration (FDA) or equivalent regulatory bodies, which emphasize the importance of hygienic design and material compliance to prevent contamination.

Tips for ensuring compliance include conducting thorough research on the machine’s specifications and understanding the labeling requirements for the oil products you intend to fill. It's also beneficial to consult industry standards such as ISO certifications that pertain to machinery safety and performance. Ensuring that the machine is certified can greatly enhance consumer confidence and simplify the process of passing inspections.

Moreover, when choosing an oil filling machine, consider investing in advanced technologies that offer precision and reliability. This not only optimizes the filling process but also helps in maintaining compliance with the stringent regulations. Regular maintenance checks and staff training should be prioritized to keep operations running smoothly and in line with industry standards, minimizing the risks associated with non-compliance.

Oil Filling Machine Performance Comparison

Evaluating Production Capacity: How to Determine Your Filling Needs

When selecting the right oil filling machine for your business, evaluating your production capacity is crucial. Understanding your filling needs starts with an assessment of your current and projected production volumes. Analyze historical data to determine daily, weekly, or monthly filling requirements. This insight will help you choose a machine that can accommodate fluctuations in demand, ensuring that you can efficiently meet order volumes without compromising on quality or speed.

In addition to assessing volume, consider the types of products you're filling. Different oils come in varying viscosities and volumes, which can affect the filling process. This is an essential factor, as some machines are better suited for specific types of oils or packaging options. Engaging with your production team to discuss workflow and operational efficiencies will provide valuable information that can steer you towards the right filling machine, ensuring it integrates smoothly with your existing processes, thus enhancing your overall productivity.

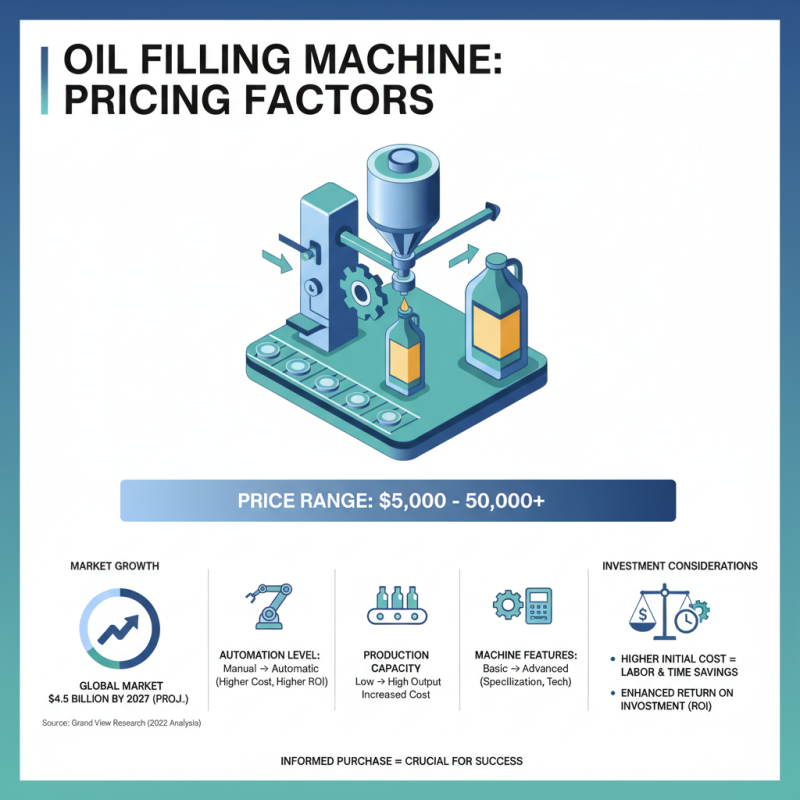

Factors Influencing Oil Filling Machine Pricing and ROI Analysis

When selecting an oil filling machine, understanding the factors that influence pricing is crucial for making an informed purchase. According to a 2022 market analysis by Grand View Research, the global oil filling machine market is projected to reach $4.5 billion by 2027, driven by increasing demand for convenience in packaging. The pricing of oil filling machines can range significantly, often between $5,000 and $50,000, depending on factors such as automation level, production capacity, and machine features. Higher automation correlates with increased initial costs, but can also lead to significant savings in labor and time, thereby enhancing return on investment (ROI).

Additionally, the ROI analysis is an essential consideration for businesses looking to justify their investment in oil filling machinery. A report from Research and Markets indicates that companies utilizing semi-automatic or fully automatic machines can achieve a labor cost reduction of up to 40%, alongside improved production efficiency. While initial costs may be higher for automated options, the long-term benefits of maintaining consistent production rates and reducing waste can outweigh these costs, leading to a quicker payback period. Thus, conducting a thorough ROI analysis based on projected production needs and operational costs will help businesses identify the best machine that aligns with their financial goals.

Technology Trends: Innovations in Oil Filling Equipment for Efficiency

The evolution of oil filling equipment has witnessed significant innovations aimed at enhancing efficiency in production processes. According to a report by Allied Market Research, the global oil filling machine market is projected to reach $1.25 billion by 2027, growing at a CAGR of 4.5%. This growth highlights the increasing demand for advanced machinery that not only streamlines operations but also ensures precision and reduces waste. Recent technological advancements include the integration of automated systems, which minimize manual intervention and improve throughput. Smart oil filling machines equipped with IoT capabilities are becoming increasingly prevalent, allowing businesses to monitor performance in real-time and optimize processes based on data analytics.

Another significant trend is the development of machines with adjustable nozzles and enhanced filling speed capabilities, meeting the diverse needs of packaging various oil types—from cooking oils to industrial lubricants. The National Association of Manufacturers reports that automation in manufacturing can reduce operational costs by up to 22%, indicating that investing in innovative oil filling technologies not only boosts efficiency but also provides a competitive advantage. As companies focus on sustainable practices, many oil filling machines are now designed to minimize environmental impact by reducing energy consumption and waste production. In this fast-paced industry, staying updated with these technological advancements is essential for businesses aiming to enhance their operational efficiency and adapt to changing market demands.

Related Posts

-

The Future of Oil Filling Machines in the Evolving Packaging Industry

-

Exploring Trends in Bottle Filling Machines at China’s 138th Canton Fair 2025

-

Maximizing Efficiency with Automatic Label Applicator Benefits for Global Buyers

-

Understanding the Different Types of Capping Machines and Their Industry Applications

-

Top 10 Automatic Filling Machines: Boost Your Production Efficiency Today!

-

2025 Top 5 Syringe Filling Machines You Need to Know

30 Beach Street, Mt Vernon, NY 10550

914-239-3878 sale@bbqmachine.com

© 2025 by TurboFil Packaging Machines, LLC

© 2025 by TurboFil Packaging Machines, LLC

Skip to content

Skip to content