How to Choose the Best Vial Labeling Machine for Your Business Needs

In today's fast-paced manufacturing landscape, the efficiency and accuracy of labeling processes have become paramount, particularly in the pharmaceutical and biotech industries where vial labeling machines play a crucial role. According to a recent report by Markets and Markets, the global market for labeling machines is expected to reach $5 billion by 2026, driven by the rising demand for automated labeling solutions that enhance production speed and minimize errors. As companies strive to meet stringent regulatory requirements and maintain high-quality standards, selecting the right vial labeling machine has become an essential consideration.

Industry experts stress the importance of aligning labeling technologies with specific business needs. Dr. Emily Carter, a renowned expert in manufacturing automation, notes, "Investing in the right vial labeling machine can significantly streamline your operations and reduce the risk of compliance issues." Businesses must carefully evaluate their requirements, including production volume, label size, and the types of vials being used, to ensure they choose a machine that maximizes efficiency while adhering to industry standards. As the labeling machine market continues to evolve, understanding the key features and innovations available is vital for making an informed purchasing decision, ultimately leading to improved productivity and a competitive edge in the marketplace.

Understanding Different Types of Vial Labeling Machines Available

When selecting a vial labeling machine for your business, it's essential to understand the various types available and how they align with your operational needs. Vial labeling machines can generally be categorized into manual, semi-automatic, and fully automatic systems. According to a recent report by MarketsandMarkets, the global labeling equipment market is projected to grow from $4.5 billion in 2020 to $5.8 billion by 2025, indicating a robust demand for efficient labeling solutions across industries.

Manual vial labeling machines are often the most cost-effective solution, ideal for small-scale operations or businesses with low production volumes. These systems require an operator to position labels on vials, which allows for flexibility but may not be suitable for high-speed production lines.

In contrast, semi-automatic machines offer a blend of automation and manual handling, featuring capabilities for quicker throughput while still requiring some operator interaction. Industry analysts suggest that these machines can enhance productivity by up to 30% compared to manual methods, making them popular in mid-sized enterprises.

Fully automatic vial labeling machines represent the pinnacle of efficiency, driven by advancements in technology. These machines can label thousands of vials per hour without the need for human intervention, significantly reducing labor costs and minimizing errors associated with manual processes.

According to a study published in the Journal of Pharmaceutical Innovation, fully automated systems can achieve up to 99.5% labeling accuracy, a crucial factor for compliance in industries such as pharmaceuticals and biotechnology. Understanding these options allows businesses to make informed decisions that cater to their specific operations and growth ambitions.

Assessing Your Business Requirements for Vial Labeling Solutions

When selecting a vial labeling machine, it's essential to start by assessing your specific business requirements. Consider the volume of vials you need to label daily, as different machines cater to varying production levels. For businesses with high output demands, a faster, more automated labeling system may be necessary to ensure efficiency. Conversely, smaller operations might benefit from a more manual approach that offers flexibility and lower initial investment. Understanding the anticipated throughput can guide you in choosing a machine that balances speed and accuracy while fitting your production capacity.

In addition to production volume, it is crucial to examine the types of vials you will be labeling. Different vials may require distinct labeling techniques or formats, such as front-and-back labeling, wrap-around, or top labeling. Consider whether you need a machine that can accommodate various shapes and sizes, as this will enhance your adaptability to changing product lines. Additionally, think about the integration capabilities of the labeling machine. Compatibility with existing packaging equipment or future upgrades can save significant time and resources, making it a vital factor in your decision-making process. Taking these considerations into account will help you find a vial labeling solution that aligns perfectly with your business needs.

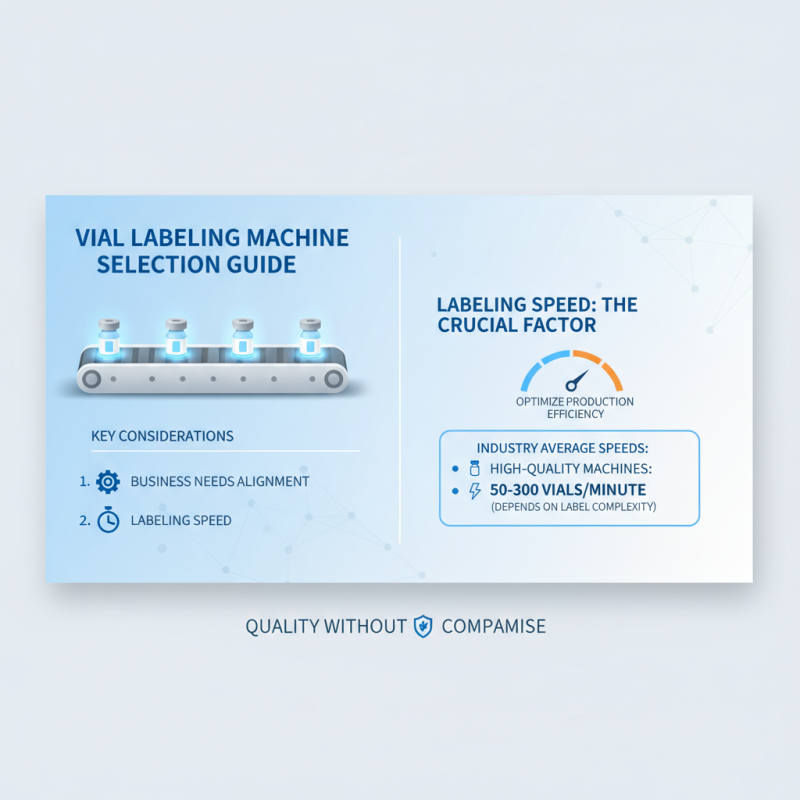

Key Features to Consider When Selecting a Vial Labeling Machine

When selecting a vial labeling machine, it is crucial to consider several key features that align with your business needs. One of the primary factors is the machine's labeling speed. According to industry reports, the average labeling speed of high-quality machines can range from 50 to 300 vials per minute, depending on the complexity of the label. This factor is especially important for businesses looking to optimize their production line efficiency without compromising on quality.

Another significant feature to consider is the machine's labeling accuracy. Data indicates that errors in labeling can lead to costly recalls and regulatory issues, potentially impacting a company's reputation and bottom line. Machines that offer a labeling accuracy rate of 99.5% or higher can significantly mitigate these risks, ensuring that each vial is correctly labeled. Additionally, the ability to accommodate various vial sizes and types can enhance versatility, allowing your business to adapt to the changing demands of the market without needing multiple machines.

Finally, the ease of integration with existing production lines cannot be overlooked. Many modern vial labeling machines come with advanced software solutions that facilitate seamless integration and real-time monitoring of the labeling process. Reports show that businesses that invest in user-friendly technology experience shorter training times and increased operational efficiency, leading to a better return on investment over time.

Evaluating Budget and Cost-Effectiveness of Labeling Equipment

When considering a vial labeling machine for your business, evaluating the budget and overall cost-effectiveness is crucial. The initial purchase price is just one aspect; you should also consider ongoing operational costs, maintenance, and potential downtime. A machine that seems affordable upfront may incur higher expenses over time due to frequent repairs or inefficiencies. It’s essential to assess the total cost of ownership by factoring in these elements to ensure that your investment remains viable in the long run.

Additionally, think about the scalability of your labeling equipment. If your business is expected to grow, investing in a machine that can handle increased production volume without significant upgrades is imperative. This not only saves costs associated with purchasing new equipment but also minimizes the disruption to your operations. By carefully analyzing both the upfront costs and future financial implications, you can select a labeling machine that perfectly aligns with your business needs and contributes to sustained profitability.

Ensuring Compliance with Industry Standards and Regulations

When selecting a vial labeling machine for your business, ensuring compliance with industry standards and regulations is paramount. Different sectors, such as pharmaceuticals and food production, are governed by strict labeling laws that dictate the information which must be displayed. This includes details such as batch numbers, expiration dates, and ingredient lists. A compliant labeling machine should be capable of producing clear, durable, and accurate labels that meet these regulatory requirements, minimizing the risk of costly recalls or legal repercussions.

Investing in features that promote compliance should be a key consideration. Look for machines that offer customizable label formats and printing options to accommodate frequent updates in regulations. Additionally, verify that the machine adheres to standards such as FDA guidelines or ISO certifications relevant to your industry. By prioritizing compliance in your search for a vial labeling machine, you not only protect your business but also enhance your credibility with consumers and regulatory bodies alike. In a landscape where adherence to regulations plays a crucial role, a compliant labeling solution can serve as a vital asset for your operations.

Related Posts

-

5 Amazing Tips for Choosing the Right Lotion Filling Machine for Your Business

-

How to Choose the Right Bottle Labeler for Your Business Needs

-

Top 10 Automatic Filling Machines: Boost Your Production Efficiency Today!

-

Exploring the Future of Production: How Automatic Bottle Labeling Machines Enhance Efficiency by 30% in Beverage Industry

-

Maximizing Efficiency: The Future of Oil Filling Machines in High-Volume Production

-

2025 How to Choose the Best Lotion Filling Machine for Optimal Efficiency

30 Beach Street, Mt Vernon, NY 10550

914-239-3878 sale@bbqmachine.com

© 2025 by TurboFil Packaging Machines, LLC

© 2025 by TurboFil Packaging Machines, LLC

Skip to content

Skip to content