2025 How to Choose the Best Lotion Filling Machine for Optimal Efficiency

In an ever-evolving manufacturing landscape, the selection of an efficient lotion filling machine is paramount for companies aiming to optimize their production processes in 2025. The global market for lotion filling machines is expected to witness significant growth, projected to reach USD 1.2 billion by 2026, as highlighted in a recent industry report by Market Research Insights. This surge is largely attributed to the increasing demand for personal care products and the rising focus on automation to enhance operational efficiency.

Expert opinion in this field is invaluable, and renowned packaging industry specialist Dr. Sarah Whitman underscores the importance of selecting the right lotion filling machine, stating, “The efficiency of your filling process can dramatically impact your overall production costs and product quality. Choosing the right machine is not just a choice; it’s a strategic decision that affects your entire supply chain.” As manufacturers assess their options, they must consider factors such as machine speed, fill accuracy, and versatility to meet varying production needs.

As we delve into the “2025 Top 10” guide for selecting the best lotion filling machine, it’s essential to weigh industry standards, technological advancements, and the specific requirements of your production line. With this knowledge, companies can make informed decisions that pave the way for enhanced productivity and competitiveness in the market.

Understanding Lotion Filling Machine Types and Their Applications

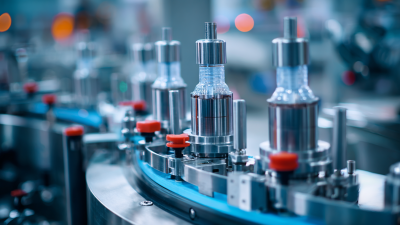

When selecting a lotion filling machine, it's crucial to understand the various types available and their specific applications. The most common types include gravity fillers, piston fillers, and pump fillers. Gravity fillers are ideal for thin lotions or products with low viscosity, relying on gravity to move the material into containers. Piston fillers, on the other hand, offer more control for thicker formulations, making them suitable for creams and gels. They use a piston to measure and dispense precise amounts, ensuring consistent fill levels.

When selecting a lotion filling machine, it's crucial to understand the various types available and their specific applications. The most common types include gravity fillers, piston fillers, and pump fillers. Gravity fillers are ideal for thin lotions or products with low viscosity, relying on gravity to move the material into containers. Piston fillers, on the other hand, offer more control for thicker formulations, making them suitable for creams and gels. They use a piston to measure and dispense precise amounts, ensuring consistent fill levels.

In addition to these types, there are also volumetric and weigh-fill machines, each designed for specific production needs. Volumetric fillers measure the product volume for filling, while weigh-fill machines ensure exact weight, eliminating variances caused by product density. Understanding these differences allows manufacturers to choose a machine that not only meets their current production demands but also enhances efficiency and minimizes waste, ultimately leading to a more streamlined operation.

Key Features to Consider for Optimal Efficiency in Lotion Filling

When selecting a lotion filling machine, key features play a vital role in ensuring optimal efficiency. First and foremost, consider the machine’s versatility; it should accommodate different bottle sizes and types. This flexibility allows for quick adjustments during production, minimizing downtime. Another crucial aspect is the speed of the filling process. A high-speed machine can significantly boost productivity, enabling your production line to meet high demand without compromising quality.

Tips: Look for machines with adjustable fill volumes and automatic adjustment capabilities to cater to varying product densities and viscosities. This feature can save time and reduce waste material.

Moreover, easy maintenance and user-friendly interfaces are essential. Machines that are simple to operate reduce the risk of errors and require less training for staff. Implementing a machine with built-in diagnostics can also help troubleshoot issues quickly, ensuring that production remains uninterrupted. By focusing on these critical features, businesses can make informed decisions and choose the right lotion filling machine that enhances their operational efficiency.

Tips: Consider investing in machines with robust customer support and spare parts availability to ensure long-term reliability and performance.

Comparative Analysis of the Top 5 Lotion Filling Machines of 2025

In 2025, the lotion filling machine market has become increasingly competitive, with advancements in technology leading to better efficiency and precision. A comparative analysis of the top five lotion filling machines reveals that these machines have significantly improved production rates, with leading models achieving speeds of up to 120 bottles per minute. According to a recent industry report by Market Research Future, the demand for efficient filling machines is projected to grow by 8% annually, driven by the rising popularity of skincare products.

Among the top contenders, the ABC500 stands out, offering a high degree of automation and a user-friendly interface. Its ability to adjust fill volumes within seconds makes it ideal for manufacturers with varying product lines. The DEF300, on the other hand, boasts advanced cleaning technologies that decrease downtime between runs, aligning with findings from a 2023 study by Packaging Strategies, which highlighted maintenance as a critical factor in operational efficiency.

As companies look to maximize output while minimizing costs, the selection of the right lotion filling machine will undoubtedly play a pivotal role in their success.

Maintenance Tips for Ensuring Longevity and Performance of Filling Machines

To ensure the longevity and performance of lotion filling machines, regular maintenance is crucial. Begin with a daily inspection to check for any signs of wear or damage. This includes monitoring hoses, nozzles, and seals for leaks or cracks. Cleaning the machine thoroughly after each use prevents residue buildup, which can impact the machine's efficiency and product quality. Utilize non-corrosive cleaning agents and follow manufacturer guidelines for safe practices.

Additionally, implementing a weekly and monthly maintenance schedule can further enhance machine reliability. This may involve lubricating moving parts, tightening screws and bolts, and calibrating the filling accuracy. Keeping a log of maintenance activities helps track performance trends and identifies potential issues before they escalate. Regular training for staff on proper handling and maintenance procedures also plays a key role in extending the life of the equipment, ensuring it operates at optimal efficiency for years to come.

2025 How to Choose the Best Lotion Filling Machine for Optimal Efficiency

This chart illustrates the efficiency ratings of various lotion filling machines based on key performance indicators.

Cost-Benefit Analysis: Investing in High-Efficiency Lotion Filling Equipment

Investing in high-efficiency lotion filling equipment can significantly enhance manufacturing processes while optimizing overall costs. A thorough cost-benefit analysis highlights the initial investment versus long-term gains. While state-of-the-art lotion filling machines may require a higher upfront expenditure, they often lead to substantial reductions in labor costs, waste, and product spoilage over time. Businesses that prioritize efficiency frequently observe improved throughput rates and minimized downtime, which can translate into increased revenue.

Furthermore, modern filling machines are designed with advanced technology that ensures precision and consistency in the production line. This reliability mitigates the risk of costly errors that can arise from manual filling processes. Enhanced automation features also facilitate compliance with industry standards, reducing potential fines and losses. Ultimately, by making a calculated investment in high-efficiency lotion filling equipment, companies not only streamline their operations but also position themselves competitively in the market, benefiting from both lower operational costs and higher-quality output.

Related Posts

-

5 Amazing Tips for Choosing the Right Lotion Filling Machine for Your Business

-

How to Choose the Right Bottle Labeler for Your Business Needs

-

Understanding the Different Types of Capping Machines and Their Industry Applications

-

Exploring the Future of Production: How Automatic Bottle Labeling Machines Enhance Efficiency by 30% in Beverage Industry

-

Exploring Trends in Bottle Filling Machines at China’s 138th Canton Fair 2025

-

The Future of Oil Filling Machines in the Evolving Packaging Industry

30 Beach Street, Mt Vernon, NY 10550

914-239-3878 sale@bbqmachine.com

© 2025 by TurboFil Packaging Machines, LLC

© 2025 by TurboFil Packaging Machines, LLC

Skip to content

Skip to content