Tips for Choosing the Best Automatic Bottle Filling Machine?

Choosing the right automatic bottle filling machine can be challenging. This decision impacts efficiency and product quality. With various options available, it’s essential to identify your specific needs. Consider the types of bottles and liquid to fill. The machine’s speed and accuracy are crucial.

Evaluating different models requires careful thought. It's easy to overlook factors like maintenance and cost. Some machines may seem perfect but lack durability. Look for user reviews and feedback when assessing quality. A reliable machine will save you time and money in the long run.

You may find that cheaper options come with hidden costs. Investing in a high-quality automatic bottle filling machine is often wiser. Make your choice based on practical needs rather than just features. Reflect on your choices and ensure they align with your business goals.

Understanding Automatic Bottle Filling Machines and Their Applications

Automatic bottle filling machines streamline the packaging process for various industries, from beverages to pharmaceuticals. These machines cater to many applications, ensuring efficiency and precision. They automate the filling process, reducing manual labor and minimizing human error.

Choosing the right machine can be challenging. Different products require different filling techniques. Liquids, powders, or viscous products each have specific needs. For example, a liquid filling machine may use gravity or pump systems. Consider the compatibility of the machine with your product type. Additionally, check machine speed, as it can affect productivity.

Maintenance is another important aspect to reflect on. While automatic machines save time, they also require regular upkeep. A lack of maintenance can lead to breakdowns, affecting efficiency. Understanding your team's skills in handling the machines is crucial. Not everyone is trained to operate complex machinery. These factors should guide your choice, ensuring you find the right fit for your operations.

Key Factors to Consider When Choosing a Bottle Filling Machine

When choosing an automatic bottle filling machine, several key factors come into play. Firstly, assess the type of liquid you will be filling. Viscous liquids require different handling compared to water-like substances. Consider the machine's compatibility with your product. Some machines struggle with thick or foamy liquids, leading to inefficiencies. It’s crucial to select a machine designed for your specific filling needs.

Another important factor is the machine's capacity. How many bottles do you need to fill per hour? High-capacity machines can be a great asset for large-scale operations. However, if your needs are smaller, a machine with a lower output may suffice. A mismatch in capacity could lead to wastage or bottlenecks in production.

Additionally, think about the machine’s ease of use. Complex machines can be daunting for operators. If your team struggles with setup or operation, it may hinder productivity. Regular maintenance is also vital. A machine that is difficult to clean can lead to contamination issues. Choose a model that allows for easy access and maintenance. These details can significantly affect your operational efficiency.

Types of Automatic Bottle Filling Machines and Their Features

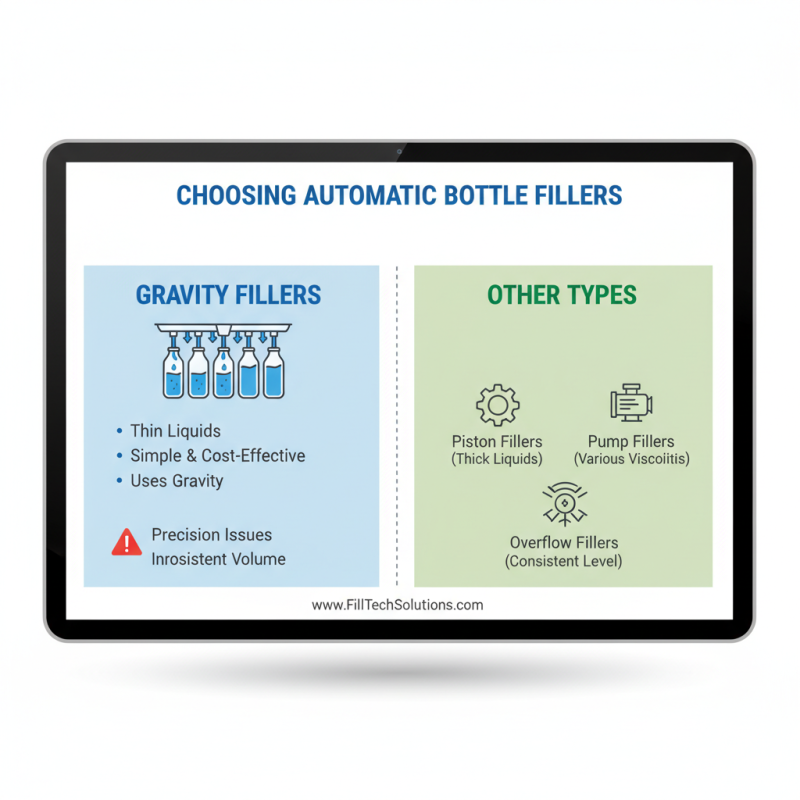

Choosing the right automatic bottle filling machine is crucial for manufacturing. The industry offers various types of machines tailored for different needs. Gravity fillers, for example, are effective for thin liquids. They utilize gravity, making them simple and cost-effective. However, precision can be an issue, as filling accuracy may vary, leading to inconsistent product volumes.

Pneumatic fillers are another option. They use air pressure to fill bottles, making them versatile for different viscosities. A study by the Packaging Machinery Manufacturers Institute (PMMI) states that pneumatic systems can enhance efficiency by up to 30%. Yet, the complexity of these machines can lead to maintenance challenges. Regular check-ups are necessary to avoid downtime.

The selection of a filling machine also depends on operational scale. For small businesses, semi-automatic machines might suffice. They require more labor but offer flexibility. However, as production scales up, fully automatic systems become essential. Industry trends show that over 60% of manufacturers are shifting towards automation for greater reliability and speed. This switch highlights the need to balance efficiency with the machine's ease of use and maintenance needs. Thus, finding a machine that fits your operation can be a daunting task.

Assessing Production Capacity and Efficiency Requirements

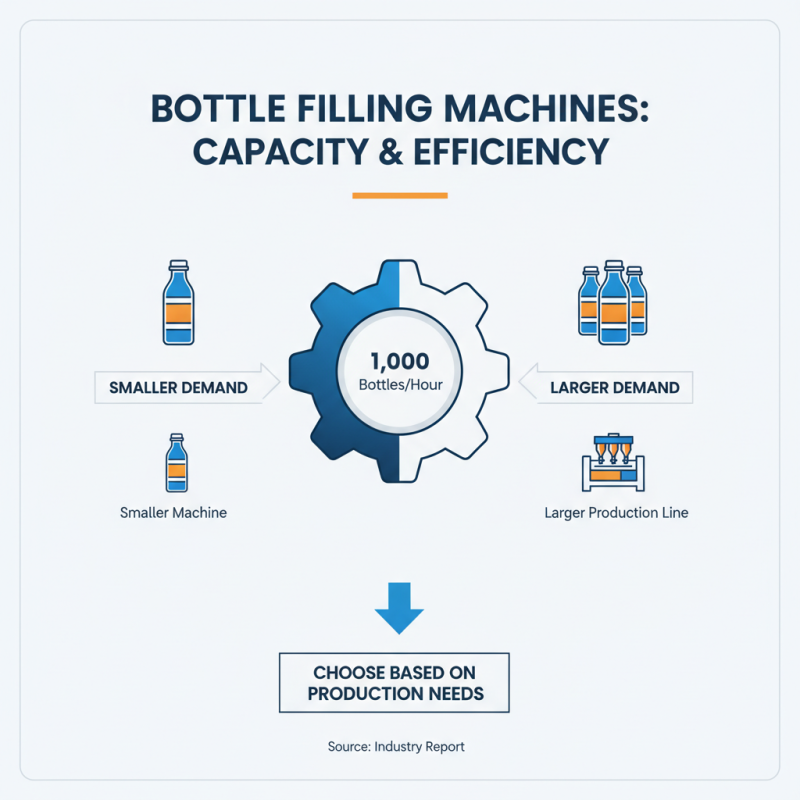

When selecting an automatic bottle filling machine, understanding production capacity and efficiency is crucial. A recent industry report indicates that factories operate with varying production demands. Some may need to fill 1,000 bottles per hour, while others might require 10,000. This massive difference influences the choice of machinery.

Efficiency is also a vital consideration. Machines that run at higher speeds often face wear and tear faster. For instance, a machine rated for 8,000 bottles per hour might not sustain consistent quality over time. Monitoring failure rates can provide insights into durability. Manufacturers should evaluate if they can afford potential downtime or maintenance costs.

Investing in technology that allows for scalability is wise. A filling machine capable of growing with your production line will save time and money. Flexibility in adjusting bottle sizes and fill volumes can enhance overall efficiency. Beware, though; not all flexible options deliver on their promises. Research is essential to avoid making hasty decisions that could hinder production.

Maintenance and Support for Long-term Operation of Filling Machines

Maintaining an automatic bottle filling machine is crucial for its longevity. Regular inspections should be part of the routine. Check for wear and tear. Components like seals and nozzles often need replacement. Neglecting these parts can lead to malfunctions. A small leak can disrupt production. Monitoring the machine's performance helps catch issues early.

Technical support is also essential. Operators should be trained to understand basic troubleshooting. Sometimes, a simple reset can resolve the problem. However, for complex issues, a professional may be required. It's important to keep contact information for service technicians easily accessible. Waiting too long for support can lead to costly downtime.

Scheduled maintenance can prevent unexpected breakdowns. Create a check-list for routine tasks. Ensure that lubricants are applied correctly. Clean the machine regularly, especially in sensitive areas. Over time, dust and debris can accumulate and affect efficiency. Consistent care will not only extend the machine's life but also improve product quality.

Tips for Choosing the Best Automatic Bottle Filling Machine

| Feature | Importance | Suggestions |

|---|---|---|

| Filling Speed | High | Choose machines with adjustable speeds for varying requirements. |

| Accuracy | High | Select machines known for precision to minimize waste. |

| Ease of Cleaning | Medium | Opt for designs that allow quick disassembly. |

| Maintenance Requirements | High | Consider manufacturers offering strong support and service plans. |

| Cost | High | Evaluate total cost of ownership over initial purchase price. |

| Bottle Compatibility | High | Ensure the machine can accommodate various bottle shapes and sizes. |

Related Posts

-

The Future of Oil Filling Machines in the Evolving Packaging Industry

-

Top 10 Automatic Filling Machines: Boost Your Production Efficiency Today!

-

How to Choose the Best Oil Filling Machine for Your Business Needs

-

Exploring the Future of Production: How Automatic Bottle Labeling Machines Enhance Efficiency by 30% in Beverage Industry

-

2025 Top Syringe Filling Machine Trends and Features You Need to Know

-

How Bottle Labeling Machines Revolutionize Efficiency in Packaging Industries

30 Beach Street, Mt Vernon, NY 10550

914-239-3878 sale@bbqmachine.com

© 2025 by TurboFil Packaging Machines, LLC

© 2025 by TurboFil Packaging Machines, LLC

Skip to content

Skip to content