How to Choose the Right Bottle Labeler for Your Business Needs

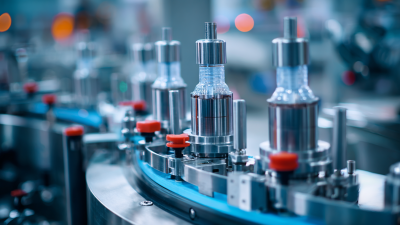

In the competitive landscape of product packaging, selecting the right bottle labeler is crucial for businesses aiming to streamline operations and enhance brand visibility. According to a report by Smithers Pira, the global labeling market is expected to reach approximately $170 billion by 2024, driven by increasing demand for packaged goods and efficient labeling solutions. A well-chosen bottle labeler not only improves productivity but also ensures compliance with regulatory standards, as nearly 62% of consumers consider labeling crucial for making informed purchase decisions.

Furthermore, the rise of e-commerce and direct-to-consumer models underlines the importance of high-quality packaging, with organizations reporting productivity improvements of up to 30% when using automated labeling systems. Therefore, understanding the specific needs of your business and the options available in bottle labelers can significantly impact your operational efficiency and consumer appeal.

Understanding Your Product Requirements for Labeling Efficiency

When selecting the right bottle labeler for your business, understanding your product requirements is paramount for achieving labeling efficiency. Each product may have unique dimensions, shapes, and materials that can influence the type of labeling method you adopt. For instance, cylindrical bottles may necessitate a different labeling approach compared to square or irregularly shaped containers. By assessing the specifics of your products, including height, width, and labeling surface, you can narrow down your options and find a machine that caters to your needs.

Moreover, consider the volume of output your business demands. If you’re running a high-speed production line, investing in a semi-automated or fully automated labeler might be justified to keep up with the pace. Conversely, smaller operations might benefit from a manual or tabletop labeler that offers flexibility and lower upfront costs. Additionally, it’s important to think about the labeling materials, such as pressure-sensitive labels, shrink sleeves, or in-line printers, ensuring that the chosen labeler effectively accommodates your preferred formats. Understanding these aspects will safeguard your investment and enhance your operational efficiency.

How to Choose the Right Bottle Labeler for Your Business Needs

| Labeler Type | Suitable Products | Labeling Speed (Labels/min) | Price Range | Key Features |

|---|---|---|---|---|

| Manual Labeler | Small bottles, jars | 15 | $20 - $100 | Portable, cost-effective |

| Semi-Automatic Labeler | Medium-sized bottles | 30 | $500 - $1,500 | User-friendly, adjustable speed |

| Fully Automatic Labeler | Large bottles, multiple shapes | 100+ | $10,000+ | High efficiency, advanced technology |

| Labeling Machine with Printer | Customized products | 50 | $2,000 - $5,000 | Prints and applies labels |

Evaluating Labeling Speed and Production Volume Needs

When evaluating labeling speed and production volume needs for your business, it’s essential to understand how these factors directly influence the type of bottle labeler you should choose. The labeling speed is crucial, as different machines offer varying speeds that can dramatically affect your production line. If your business operates at high volumes, look for machines that can process hundreds of bottles per minute. Conversely, for smaller operations, a semi-automatic labeler may suffice.

**Tips:** Consider your production growth plans. If you foresee an increase in product demand, invest in a labeling machine that can accommodate higher speeds and volumes in the future. Additionally, look for machines with adjustable settings that allow for easy changes between different product sizes and label formats.

Another aspect to consider is the maintenance and ease of use of the labeling machine. A more complex machine might require specialized knowledge for operation and maintenance, which could lead to increased downtime if issues arise. Selecting a user-friendly model ensures that your workforce can manage the equipment efficiently, keeping production delays to a minimum.

**Tips:** Always check customer reviews and seek recommendations for reliable brands that offer robust support and spare parts availability. A good warranty can also add peace of mind for your investment, making sure your machine remains operational for years to come.

Exploring Different Types of Bottle Labels and Their Compatibility

When selecting the right bottle labeler, it’s crucial to understand the various types of bottle labels and their compatibility with different packaging materials. For instance, labels designed for HDPE bottles have recently been highlighted for their recycling compatibility, as demonstrated by the approval from a leading recycling organization. This is particularly relevant for businesses aiming to enhance their sustainability practices while remaining compliant with industry standards. According to industry reports, adopting recyclable labels can improve the eco-friendliness of products and potentially attract environmentally-conscious consumers.

In addition to compatibility, the choice of label type can have significant implications for branding and consumer engagement. Clear labels with high-quality printing can enhance product visibility and attract consumers on the shelf. Moreover, shrink sleeve labels have been gaining popularity due to their ability to conform to various bottle shapes, offering a clean and modern look.

Tips: When choosing a labeler, consider the types of labels that your product will require, as not all labelers can accommodate every label material. Additionally, evaluate the efficiency and speed of the labeler to ensure it meets your production demands without sacrificing quality. Always keep recycling regulations in mind; opting for compatible labels can facilitate easier recycling processes, thus contributing positively to the environment.

Assessing Budget Considerations and Potential ROI of Labeling Machines

When selecting a bottle labeler, assessing budget considerations is crucial for ensuring the machine aligns with your business needs. The initial investment in labeling equipment can vary significantly, depending on features such as automation level, speed, and precision.

Businesses should evaluate their production volume to determine an appropriate range for labeling capacity. This not only helps allocate funds effectively but also minimizes the risk of over-investment in high-capacity machines that may exceed operational requirements.

Additionally, understanding the potential return on investment (ROI) is essential. A well-chosen labeling machine can lead to increased efficiency, reduced labor costs, and improved product presentation—all of which can enhance sales. Analyzing metrics such as production time savings and potential increases in throughput will provide insights into how quickly the investment can pay off. Furthermore, considering the durability and maintenance costs of the labeling machine contributes to a comprehensive evaluation of long-term ROI, ensuring that the purchase remains a profitable decision over time.

Researching Industry-Specific Features for Optimized Label Application

When selecting a bottle labeler for your business, it's crucial to delve into industry-specific features that can optimize label application for your unique operations. Different sectors have varying requirements; for instance, the food and beverage industry often demands high-speed labeling with strict adherence to safety and compliance regulations. Understanding the nuances of your market will aid in identifying the type of labeler that aligns with both your production speed needs and regulatory standards.

Moreover, technology plays a significant role in enhancing labeling processes. Advanced solutions, such as automated labeling systems utilizing artificial intelligence, can significantly reduce errors and improve efficiency. Industries can benefit from systems that incorporate data analytics, allowing businesses to make informed decisions based on real-time production data. Emphasizing the importance of functionality, compatibility with existing production lines, and adaptability to varied product sizes can lead to more effective label application, ensuring that your chosen labeler not only meets current needs but also scales with your business's growth.

Related Posts

-

7 Essential Tips for Choosing the Perfect Bottle Labeler

-

Maximizing Efficiency with Automatic Label Applicator Benefits for Global Buyers

-

Ultimate Guide to Choosing the Right Label Applicator Machine for Your Business

-

Understanding the Different Types of Capping Machines and Their Industry Applications

-

What is a Capping Machine for Bottles and How Can It Benefit Your Production Line?

-

How to Choose the Perfect Lip Gloss Filling Machine for Your Production Needs

30 Beach Street, Mt Vernon, NY 10550

914-239-3878 sale@bbqmachine.com

© 2025 by TurboFil Packaging Machines, LLC

© 2025 by TurboFil Packaging Machines, LLC

Skip to content

Skip to content