The Ultimate Guide to Choosing the Right Label Applicator Machine for Your Business

In today's fast-paced manufacturing environment, selecting the right label applicator machine is crucial for efficient production and product presentation. A recent report by Smithers Pira indicates that the global labeling market is expected to reach $50 billion by 2024, driven by the growing demand for packaged goods and e-commerce.

Efficient labeling not only enhances brand visibility but also ensures compliance with regulatory standards, making the choice of a suitable label applicator machine a vital business decision. Companies that invest in advanced labeling technologies can see an increase in productivity by up to 30%, significantly reducing labor costs while improving accuracy and speed.

This guide aims to help business owners navigate the variety of label applicator machines available, ensuring that they make an informed investment that aligns with their operational needs and enhances their market competitiveness.

Understanding Your Labeling Needs: What to Consider for Your Industry

When selecting the right label applicator machine for your business, understanding your labeling needs is paramount.

Each industry has unique requirements driven by product types, packaging styles, and production speeds.

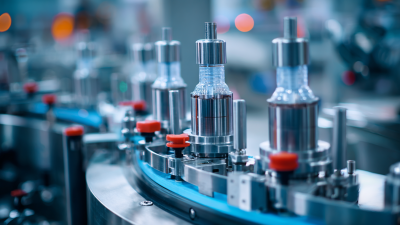

For example, food and beverage companies may prioritize sanitary design and compliance with health regulations, while cosmetics manufacturers might focus on precision to ensure labels are applied flawlessly on irregularly shaped containers. Identifying the specific requirements of your product will help narrow down the options.

Additionally, consider the scale of your operations. Smaller businesses may benefit from manual or semi-automatic label applicators that can adapt to varying production volumes. In contrast, larger manufacturing setups may require fully automated systems capable of high-speed labeling to keep up with increased demand.

The choice also depends on future growth prospects; investing in a versatile machine that can handle your evolving needs is crucial. Understanding these factors will lead you to a label applicator machine that not only meets your current demands but also supports future expansion.

Exploring Different Types of Label Applicator Machines: Pros and Cons

When selecting a label applicator machine, understanding the different types available is crucial for making an informed decision.

Pressure-sensitive label applicators, for example, are among the most common options. These machines enable quick and efficient application of labels onto various surfaces without the need for heat or moisture.

According to a recent report by Freedonia Group, the demand for pressure-sensitive labels is expected to rise by over 4.3% annually, highlighting their growing importance in industries such as food and beverage, pharmaceuticals, and cosmetics.

On the other hand, hot glue label applicators offer durability and are ideal for products that require a strong adhesion under various environmental conditions. However, these machines may involve higher maintenance costs and operational complexities.

A study by Research and Markets indicates that the global hot melt adhesive market is projected to exceed $9 billion by 2025, reflecting a robust demand driven by its effectiveness in industries requiring reliable label application.

Each type has its unique advantages and limitations, making it essential for businesses to consider their specific labeling needs and operational capacity before making a purchase.

Evaluating Automation Levels: Manual vs. Semi-Automatic vs. Fully Automatic

When selecting a label applicator machine for your business, understanding the different levels of automation is crucial. Manual applicators are the most straightforward option, requiring operators to apply labels by hand. This method offers flexibility, making it suitable for small businesses with low-volume production needs. However, it can be labor-intensive and may lead to inconsistencies in label application, which can affect product presentation and brand image.

On the other hand, semi-automatic applicators strike a balance between manual and fully automatic solutions. They typically require some operator intervention but can significantly increase throughput by automating parts of the labeling process. This type is ideal for businesses experiencing growth, as it can handle moderate production volumes while still being cost-effective compared to full automation.

Fully automatic label applicators represent the pinnacle of efficiency and speed. These machines are designed to operate independently, applying labels at high speeds without the need for constant human oversight. While they come with a higher initial investment, their efficiency and reliability can lead to substantial long-term savings, especially for high-volume production lines. Choosing the right level of automation depends on your specific business needs, production volume, and budget considerations.

The Automation Levels of Label Applicator Machines

Assessing Production Speed: How Label Applicators Affect Your Output

When considering a label applicator machine, assessing production speed is critical to enhancing your operational efficiency. According to a recent report by Smithers Pira, companies that invest in automated labeling solutions can increase their production line speeds by up to 30%. This gain not only boosts output but also reduces labor costs, making it a strategic investment for businesses looking to scale. Label applicators designed for high-speed production can apply labels at rates of 300 units per minute, significantly outperforming manual labeling methods.

When considering a label applicator machine, assessing production speed is critical to enhancing your operational efficiency. According to a recent report by Smithers Pira, companies that invest in automated labeling solutions can increase their production line speeds by up to 30%. This gain not only boosts output but also reduces labor costs, making it a strategic investment for businesses looking to scale. Label applicators designed for high-speed production can apply labels at rates of 300 units per minute, significantly outperforming manual labeling methods.

Tip: When selecting a label applicator, consider your product types and the required labeling speed. It’s essential to choose a machine that not only meets current demand but also has the capability to grow with your business needs.

Moreover, the precision of label applicators can dramatically reduce wastage. Research from the Automation Research Corporation states that errors in manual labeling can lead to waste rates as high as 20%. By automating this process, businesses can minimize these mistakes and improve overall product quality, thus boosting customer satisfaction and brand reputation.

Tip: Opt for a label applicator that features adjustable settings. This versatility allows your business to adapt quickly to different product sizes and labels, ensuring optimal efficiency across your production line.

Budgeting for Efficiency: Cost Analysis of Label Applicator Investments

When investing in a label applicator machine, understanding the cost implications is crucial for ensuring long-term efficiency for your business. Start by evaluating your production needs and the specific labeling requirements of your products. Different machines offer various features, such as speed, precision, and compatibility with different label types, which can significantly affect the overall investment. Factoring in these elements will help you delineate your budget and align it with your operational goals.

It's essential to conduct a thorough cost analysis that goes beyond the initial purchase price. Consider additional expenses such as maintenance, training, and potential downtime when evaluating machine options. Investing in a high-quality label applicator may have a higher upfront cost but can yield significant savings in labor and production efficiency over time. Balancing these factors will ultimately help you make an informed decision that maximizes your returns while enhancing your operational workflow.

Related Posts

-

Maximizing Efficiency with Automatic Label Applicator Benefits for Global Buyers

-

Ultimate Guide to Choosing the Right Label Applicator Machine for Your Business

-

How to Choose the Right Bottle Labeler for Your Business Needs

-

Exploring the Future of Production: How Automatic Bottle Labeling Machines Enhance Efficiency by 30% in Beverage Industry

-

Understanding the Different Types of Capping Machines and Their Industry Applications

-

Exploring the Top 5 Innovations in Tube Filling Machines for Enhanced Efficiency

30 Beach Street, Mt Vernon, NY 10550

914-239-3878 sale@bbqmachine.com

© 2025 by TurboFil Packaging Machines, LLC

© 2025 by TurboFil Packaging Machines, LLC

Skip to content

Skip to content