Why Invest in a Lip Gloss Filling Machine for Your Cosmetic Business?

In the ever-evolving cosmetic industry, staying ahead of the competition requires not only innovative product offerings but also efficient production processes. One piece of equipment that has gained significant attention from entrepreneurs and established brands alike is the lip gloss filling machine. This machine is designed to streamline the filling process, ensuring that each product is filled accurately and swiftly. Investing in a lip gloss filling machine can enhance production efficiency, reduce labor costs, and improve product consistency—all vital factors for any cosmetic business aiming for growth and customer satisfaction.

Moreover, the versatility of a lip gloss filling machine allows businesses to produce a variety of lip gloss formulations, catering to a diverse customer base. From different textures to unique flavors and packaging options, this machine can accommodate the changing needs of the market. By automating production, companies can not only save time but also minimize the risk of human error, which can lead to costly product recalls and reputational damage. Ultimately, the integration of a lip gloss filling machine into your production line not only showcases a commitment to quality and efficiency but also promotes a scalable business model that can adapt to emerging trends in the beauty industry.

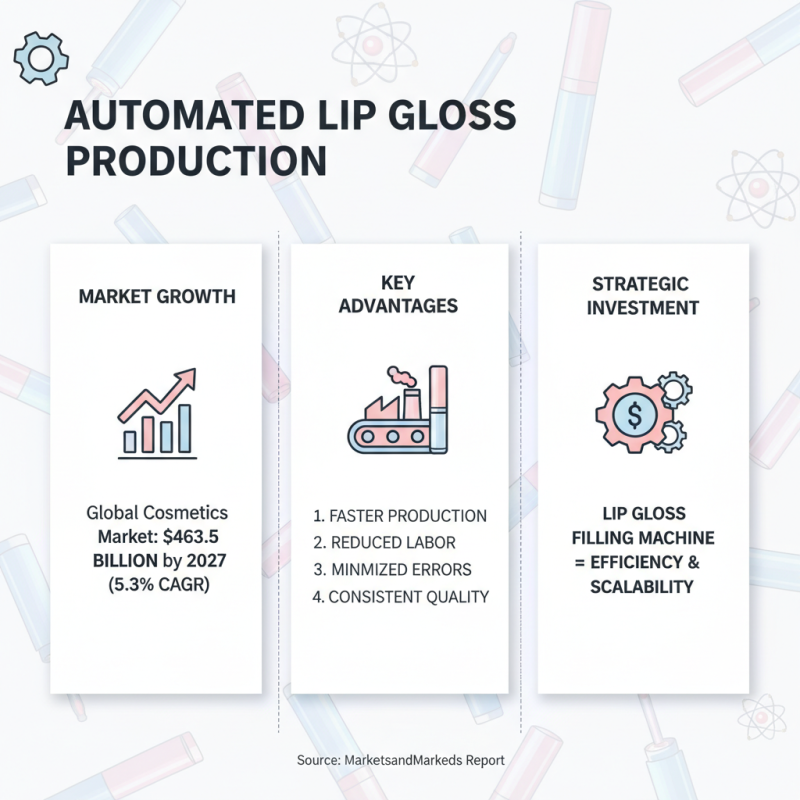

Benefits of Automating Lip Gloss Production for Cosmetic Brands

Automating lip gloss production offers significant advantages for cosmetic brands looking to enhance efficiency and scalability. According to a report by MarketsandMarkets, the global cosmetics market is expected to reach $463.5 billion by 2027, growing at a CAGR of 5.3%. As the demand for lip products continues to rise, streamlining the production process becomes essential for brands to stay competitive. Investing in a lip gloss filling machine allows for quicker production cycles, reducing manual labor and minimizing the risk of errors. This automation not only saves time but also helps in maintaining consistent quality across batches.

Moreover, by automating the filling process, cosmetic brands can better manage their operational costs. A study by IBISWorld indicates that labor costs can account for up to 30% of total production expenses in the cosmetics industry. By implementing a filling machine, brands can significantly lower these costs, enabling them to allocate resources more effectively. Furthermore, automated systems facilitate higher output rates, ensuring that businesses can meet growing consumer demands without compromising on quality. As consumer preferences increasingly shift towards eco-friendly and sustainable products, automated filling solutions also offer the possibility of reducing waste, aligning with industry trends towards sustainability.

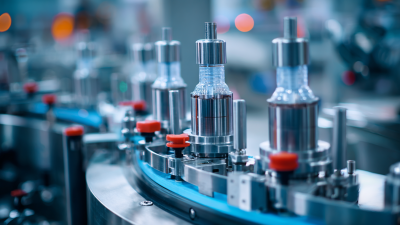

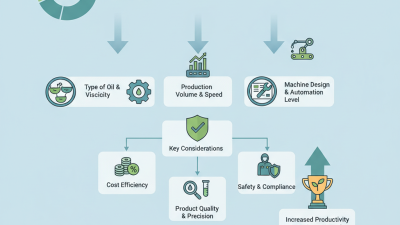

Key Features to Look for in a Lip Gloss Filling Machine

When considering the investment in a lip gloss filling machine for your cosmetic business, it's essential to prioritize certain key features that can significantly influence efficiency and product quality. First and foremost, precision in filling technology is critical. Machines equipped with volumetric or weight-based filling mechanisms ensure consistent dosages, which are vital for maintaining product quality and brand reputation. According to a recent industry report, brands that implement high-precision filling systems can see up to a 30% reduction in product waste, leading to enhanced profitability.

Another important feature to look for is the versatility of the machine. In the ever-evolving cosmetic industry, the ability to handle various formulations—such as traditional lip gloss, glossy pigments, or even organic options—can position a business for growth. Models that offer adjustable settings for different viscosities enhance operational flexibility, enabling manufacturers to quickly adapt to market trends. A study from the Cosmetic Engineering Society highlights that companies with adaptable production lines are 25% more capable of launching new products in response to consumer demand within tight timelines.

Lastly, consider the ease of cleaning and maintenance. With stringent regulations in the cosmetics sector, a machine with quick-change parts and easy access for cleaning will reduce downtime. Research shows that companies committed to maintaining machinery regularly report 20% fewer production errors and defects. Investing in a machine that emphasizes user-friendliness can provide not only operational efficiency but also ensure compliance with safety standards in cosmetic manufacturing.

Comparison of Key Features in Lip Gloss Filling Machines

Cost-Effectiveness of Investing in a Filling Machine

Investing in a lip gloss filling machine presents a strategic opportunity for cosmetic businesses looking to enhance their operational efficiency and cost-effectiveness. Unlike manual filling methods, a filling machine automates the process, significantly reducing labor costs and minimizing the risk of errors. With faster production times, businesses can scale their output and meet increasing customer demand without the need for substantial workforce expansion. This automation not only saves money in the long run but also increases consistency in product quality, which is vital in the competitive cosmetic market.

Moreover, a filling machine offers the advantage of precise measurements, ensuring that each product adheres to specified quantity standards. This precision reduces material waste and can lead to significant savings over time, particularly in industries where margins are tight. The initial investment in a high-quality filling machine can be quickly recouped by the savings gained from reduced labor costs, decreased ingredient waste, and the ability to produce a larger volume of product in less time. Consequently, companies can allocate resources more effectively, focusing on marketing and product development while maintaining steady production levels.

Impact of Packaging Quality on Consumer Perception

The packaging quality of cosmetic products, particularly lip gloss, significantly influences consumer perception and purchasing behavior. A well-designed lip gloss container not only protects the product but also conveys a sense of luxury and care in the formulation. When consumers are presented with aesthetically pleasing and functional packaging, they are more likely to perceive the product as high-quality. This perception is crucial in the competitive cosmetics market, where numerous options vie for consumer attention.

Investing in a lip gloss filling machine allows cosmetic businesses to ensure consistent packaging quality. Automated filling machines can enhance precision and uniformity, reducing the likelihood of spills and contamination that could tarnish the brand's reputation. Additionally, sophisticated packaging solutions can incorporate features such as user-friendly applicators and eco-friendly materials, which resonate with consumers who prioritize sustainability. By focusing on high-quality packaging through advanced machinery, brands can elevate their products in the eyes of consumers, leading to increased customer loyalty and repeat purchases.

Future Trends in Cosmetic Manufacturing Technology

The cosmetic manufacturing industry is poised for significant transformation, driven by innovations and advancements in technology. As consumers increasingly seek personalized and high-quality products, manufacturers must adapt to meet these demands. Future trends indicate a growing emphasis on automation and precision in production processes. The integration of artificial intelligence and robotics in filling machines, such as those for lip gloss, will enhance efficiency and reduce production time, allowing businesses to scale their operations seamlessly.

Moreover, sustainability has become a central focus in cosmetic manufacturing. Trends show a shift towards eco-friendly packaging solutions and the use of biodegradable materials. As the industry evolves, the incorporation of smart technology in filling machines will support these sustainable practices by optimizing material usage and minimizing waste. This alignment not only meets consumer expectations for environmentally responsible products but also positions businesses competitively in a rapidly changing market landscape, highlighting the necessity for investment in advanced filling equipment.

Related Posts

-

Understanding the Different Types of Capping Machines and Their Industry Applications

-

What is a Paste Filling Machine? Benefits, Uses, and Buying Guide

-

Ultimate Guide to Choosing the Right Label Applicator Machine for Your Business

-

How to Choose the Best Oil Filling Machine for Your Business Needs

-

How to Choose the Right Bottle Labeler for Your Business Needs

-

Exploring the Future of Production: How Automatic Bottle Labeling Machines Enhance Efficiency by 30% in Beverage Industry

30 Beach Street, Mt Vernon, NY 10550

914-239-3878 sale@bbqmachine.com

© 2025 by TurboFil Packaging Machines, LLC

© 2025 by TurboFil Packaging Machines, LLC

Skip to content

Skip to content