Top 10 Automatic Filling Machines: Boost Your Production Efficiency Today!

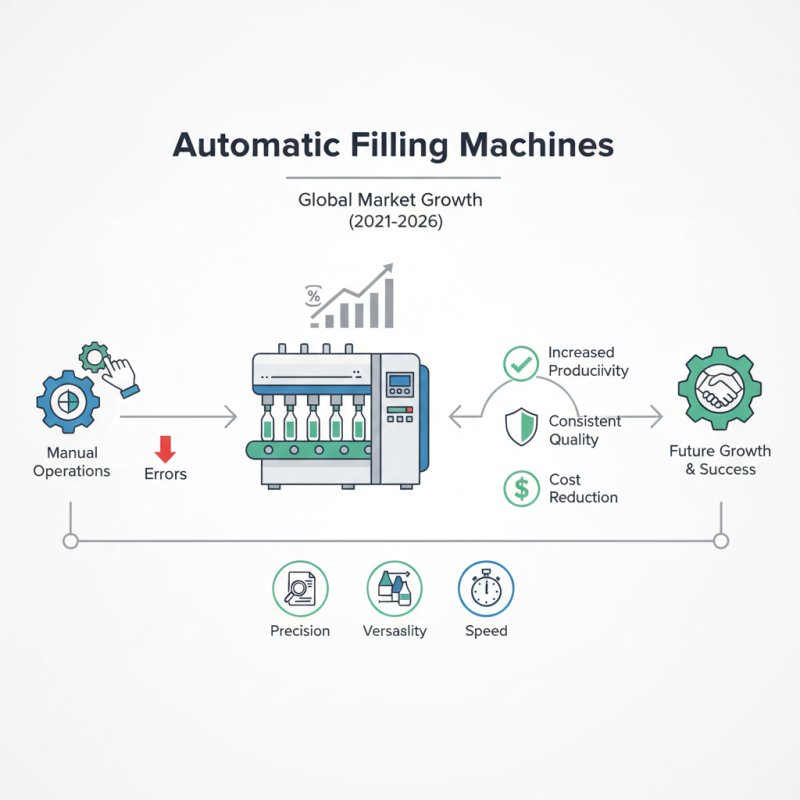

In today's fast-paced manufacturing landscape, the efficiency of production processes has become a pivotal factor for businesses striving to maintain a competitive edge. Among the various innovations that have transformed the industry, the automatic filling machine stands out as a powerful tool that can significantly boost productivity. According to a report by Research and Markets, the global market for automatic filling machines is projected to grow at a CAGR of 7.2% from 2021 to 2026, underscoring the rising demand for automation in manufacturing. This trend highlights the industry's recognition of the need for enhanced operational efficiency and cost reduction.

Industry expert Dr. Emily Turner, a leading authority on automated systems in food and beverage production, aptly stated, "Investing in an automatic filling machine not only streamlines the bottling process but also reduces errors that can occur in manual operations." This sentiment is echoed across sectors, where businesses are increasingly turning to automatic filling machines to address labor shortages and improve throughput. With advancements in technology, these machines now offer greater precision, versatility, and speed, making them indispensable for manufacturers aiming to meet growing consumer demands.

As we delve into the top 10 automatic filling machines available today, it becomes clear that choosing the right equipment can make a substantial difference in enhancing production capabilities. By integrating state-of-the-art automatic filling machines into their operations, manufacturers can not only elevate their productivity but also ensure consistent quality in their products, paving the way for future growth and success.

Understanding Automatic Filling Machines and Their Importance

Automatic filling machines are essential in the modern manufacturing landscape, driving efficiency and consistency across various industries. As businesses strive to enhance production rates, the Dual Chamber Syringe (DCS) filling machine market has seen significant growth due to its ability to streamline operations. According to recent industry reports, the market for filling machines is projected to grow at a CAGR of over 5% by 2025, reflecting a continued shift toward automation in manufacturing processes.

Liquid filling machines, particularly the fully automatic variants, are becoming increasingly versatile, accommodating a wide range of products from beverages to pharmaceuticals. The versatility of today’s filling equipment allows companies to respond swiftly to changing consumer demands. For example, the rise in popularity of ready-to-drink beverages has led manufacturers to adopt filling machines that can handle varying product viscosities and packaging types. With a focus on efficiency, automated machines reduce labor costs and minimize the risk of human error, making them a critical investment for businesses aiming to stay competitive.

Top 10 Automatic Filling Machines: Production Capacity Analysis

Key Features to Look for in an Automatic Filling Machine

When selecting an automatic filling machine, it's crucial to pay attention to several key features that can significantly affect your production efficiency. First and foremost, consider the machine's filling accuracy. An accurate filling mechanism ensures that each container is filled precisely, minimizing product waste and maximizing profitability. Look for machines equipped with advanced sensors and controls that enhance precision and allow for easy calibration.

Another essential aspect is the machine's versatility. The ideal automatic filling machine should be capable of handling various container sizes and types without extensive downtime for changeovers. This flexibility not only streamlines the production process but also allows for greater adaptability in responding to market demands. Additionally, pay attention to the speed of operation; a high-speed machine can dramatically increase your output, helping you meet deadlines and reduce labor costs.

Lastly, don't overlook the importance of ease of use and maintenance. Machines that are user-friendly with intuitive controls can reduce training time for operators, while those designed for straightforward maintenance can minimize downtime. A robust after-sales support and easy access to spare parts are also vital to ensure your production line runs smoothly without unexpected interruptions.

Top 10 Automatic Filling Machines: A Detailed Review

When it comes to enhancing production efficiency,

automatic filling machines are revolutionary tools that can streamline the packaging process across

various industries. In our detailed review of the top 10 automatic filling machines, we delve into

the features, advantages, and applications of each model. From liquid fillers to powder dispensers,

these machines cater to a broad range of products, ensuring precision and consistency in every fill.

Our analysis highlights the performance metrics

that set these machines apart, such as speed, accuracy, and ease of use. Each machine

has unique attributes, whether it’s the advanced technology that minimizes waste or the user-friendly

interface that allows for quick adjustments during production runs. By focusing on these critical

aspects, we aim to provide businesses with the insights they need to make informed decisions that

could significantly boost their operational efficiency and output quality.

Comparative Analysis: Choosing the Right Machine for Your Needs

When selecting an automatic filling machine, it’s essential to consider various factors that align with your production goals and product characteristics. Start by evaluating the type of products you will be filling, as different machines are designed to handle specific viscosities, such as liquids, creams, or powders. For instance, a pump filling machine might be best suited for viscous liquids, while a volumetric filling machine works well for low-viscosity options. Identifying your product type and viscosity will help narrow down the right machine for efficient operation.

Next, consider the production capacity and speed of the filling machine. Assess your daily output requirements and ensure that the machine you choose can meet or exceed those needs. It's also crucial to look at the machine's layout and ease of integration into your existing production line. Some machines offer advanced automation features that enhance productivity, while others might require more manual intervention. By comparing these features, you can make an informed decision that not only boosts your production efficiency but also fits seamlessly into your operational workflow.

Next, consider the production capacity and speed of the filling machine. Assess your daily output requirements and ensure that the machine you choose can meet or exceed those needs. It's also crucial to look at the machine's layout and ease of integration into your existing production line. Some machines offer advanced automation features that enhance productivity, while others might require more manual intervention. By comparing these features, you can make an informed decision that not only boosts your production efficiency but also fits seamlessly into your operational workflow.

Enhancing Production Efficiency with Automatic Filling Solutions

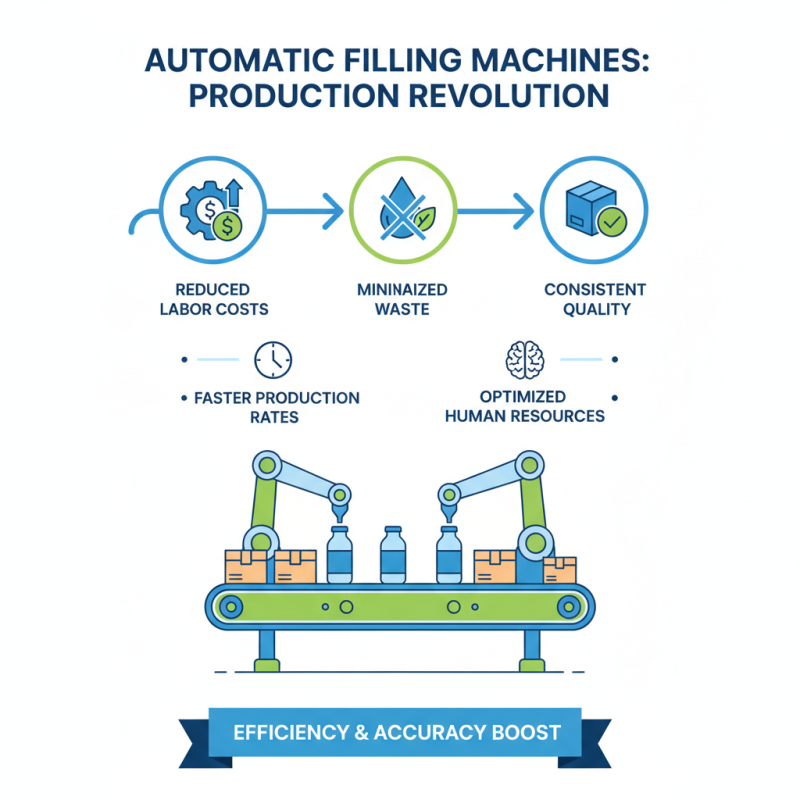

Automatic filling machines are revolutionizing production lines across various industries, enhancing overall efficiency and accuracy. By automating the filling process, companies can reduce labor costs, minimize product waste, and ensure consistent quality in every package. This shift to automatic solutions not only speeds up production rates but also allows for better utilization of human resources in more critical areas of operation.

When considering an automatic filling machine, it’s essential to assess your specific production needs. Tips to keep in mind include evaluating the type of products you are filling, as some machines are better suited for liquids, while others excel with powders or granules. Additionally, analyzing the machine’s speed and capacity to match your production volume can prevent bottlenecks and ensure smooth workflow.

Another important factor is the machine’s adaptability. Look for filling machines that offer adjustable settings, allowing for quick transitions between different product types or package sizes. This flexibility can significantly enhance production efficiency, especially in businesses that handle a variety of products. Investing in the right automatic filling solution can transform your production capabilities and support your growth objectives.

Related Posts

-

2025 Top 5 Syringe Filling Machines You Need to Know

-

Maximizing Efficiency: The Future of Oil Filling Machines in High-Volume Production

-

7 Essential Tips for Choosing the Perfect Bottle Labeler

-

Maximizing Efficiency with Automatic Label Applicator Benefits for Global Buyers

-

The Future of Oil Filling Machines in the Evolving Packaging Industry

-

Exploring Innovative Examples of Capping Machine Technologies in Today's Bottling Industry

30 Beach Street, Mt Vernon, NY 10550

914-239-3878 sale@bbqmachine.com

© 2025 by TurboFil Packaging Machines, LLC

© 2025 by TurboFil Packaging Machines, LLC

Skip to content

Skip to content